If you ever worked in a laboratory, you know tables and workbenches are prime property. Scientists, like chefs in a kitchen, often complain that there’s not enough counter space. Laboratory tables serve as a space for all kinds of experiments, data collection, research, and applications, and they can quickly become cluttered with various equipment such as autoclaves, circulators, water baths, pipettes, spectrophotometers, and more. Adding additional tables and workspaces can go a long way in helping improve workflow, results, and productivity. But what exactly should you be looking for in a laboratory work surface and which materials make the best lab table countertop? Let’s explore the options.

What is a science lab table?

What are the top materials for science lab tables?

Like kitchen countertops, there are many materials to choose from, so let’s start by reviewing the most common science lab table surfaces and countertop materials.

Phenolic Resin

Phenolic resin is an extremely popular choice for life science and chemistry labs because it can withstand chemicals, acids, bases, salts, solvents, halogens, and other materials frequently used in a lab. Phenolic resin surfaces are made by layering kraft paper soaked in resin and processing them at high temperatures to create a lightweight solid tabletop. The manufacturing process creates a hygienic, non-porous, non-conductive surface that’s durable, easy to clean, and can be formed into various shapes and sizes.

Epoxy Resin

Epoxy resin is another common laboratory material for tables and workbenches. It offers resistance to corrosive chemicals, heat, moisture, and impact damage. To create epoxy resin countertops, resin, silica, hardener, and filler are molded and oven-cured into a heavy, solid slab. The curing process makes epoxy resin impenetrable to bacteria, mold, germs, and mildew. Epoxy resin work surfaces are non-absorbent and work well in wet labs or near sinks. The material is highly durable and can tolerate high heat, including open flames. It is extremely heavy, though, so it will need a strong foundation or cabinet to support the weight of the tabletop.

High-Pressure Laminate

High-pressure laminate (HPL) countertops are crafted by combining wood fiber, phenolic resin, and melamine under high heat and pressure. The process results in an affordable, versatile general-purpose material suitable for chemical-free and dry lab facilities, such as computational, engineering, and applied physics laboratories. While HPL countertops are impact and scratch resistant and require minimal maintenance, they have some drawbacks. HPL surfaces offer low resistance to bacteria, chemicals, corrosive materials, fungi, water, moisture, and scratches. Still, for low-impact labs, including some education facilities, HPL offers an attractive, cost-effective, low-maintenance solution that can maintain its appearance for many years.

Chemical-Resistant Laminate

Chemical-resistant laminate combines some of the features of high-pressure laminate with the chemical resistance of phenolic resin. Chemical laminate combines an overlay of decorative surface paper with a melamine resin bonded to a core of kraft papers saturated with phenolic resin. The outcome is a visually appealing work surface that’s durable, functional, and offers exceptional chemical resistance. Chemical-resistant laminate can tolerate temperatures up to 135 degrees Celsius (275 degrees Fahrenheit) but should not be used for high-temperature applications that exceed that limit. While the material offers chemical resistance, it is susceptible to scratches, cuts, water, moisture, bacteria, and corrosive elements—the mid-range price and chemical resistance suit low-impact labs that require good chemical resistance.

Stainless Steel

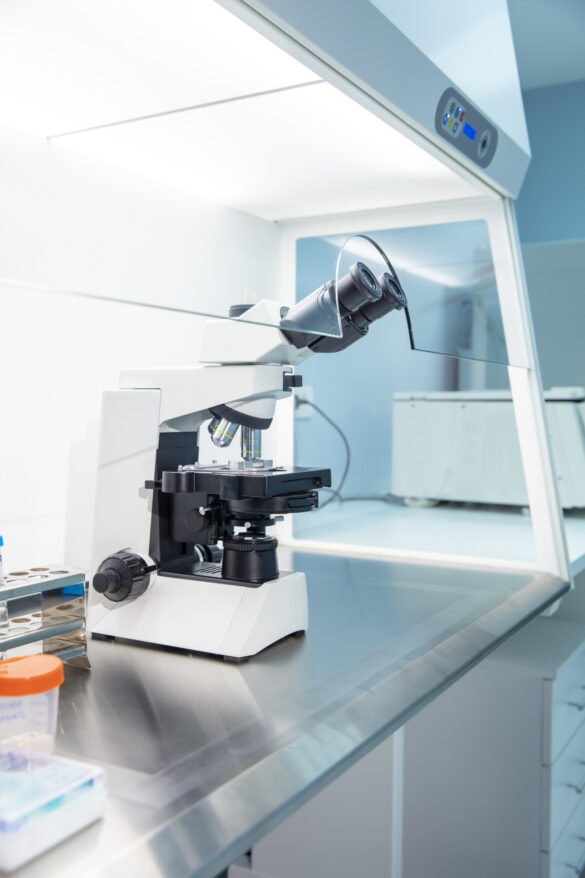

Walk into any laboratory, and you’ll likely see a lot of stainless steel, from equipment to furniture and table tops. Stainless steel is durable, hygienic, non-porous, and chemical resistant. Like other steel products, stainless steel is made from iron and carbon. To achieve “stainless steel,” chromium and other alloys are added to low-iron steel to create a stain-resistant anti-corrosive material. Stainless steel science tables can endure significant wear and tear and offer exceptional heat resistance. Stainless steel tables and workbenches make it easy to maintain a sterile environment with minimal dirt, dust, and contamination. While stainless steel meets many scientific laboratory requirements, it can dent or scratch over time. For a heavier-duty stainless steel table that can withstand heavy equipment and machine vibrations, you’ll want to consider 14-gauge stainless steel.

What is a science lab table?